Why Warehouse Modernization Is Becoming Indonesia’s New Economic Advantage

Why Warehouse Modernization Is Becoming Indonesia’s New Economic Advantage

Indonesia’s warehousing sector is entering a period of strong momentum. Data from Statistics Indonesia (BPS) shows that the transportation and general warehousing subsector grew 8.69% in 2024, far above the national economic growth of 5.03%.

Even further, the warehousing subsector is projected to grow 12.53% in 2025, while industry associations forecast further expansion of 9.03–9.31% in 2026.

This trend signals one thing clearly:

Warehousing is becoming a critical strategic pillar in strengthening Indonesia’s logistics competitiveness.

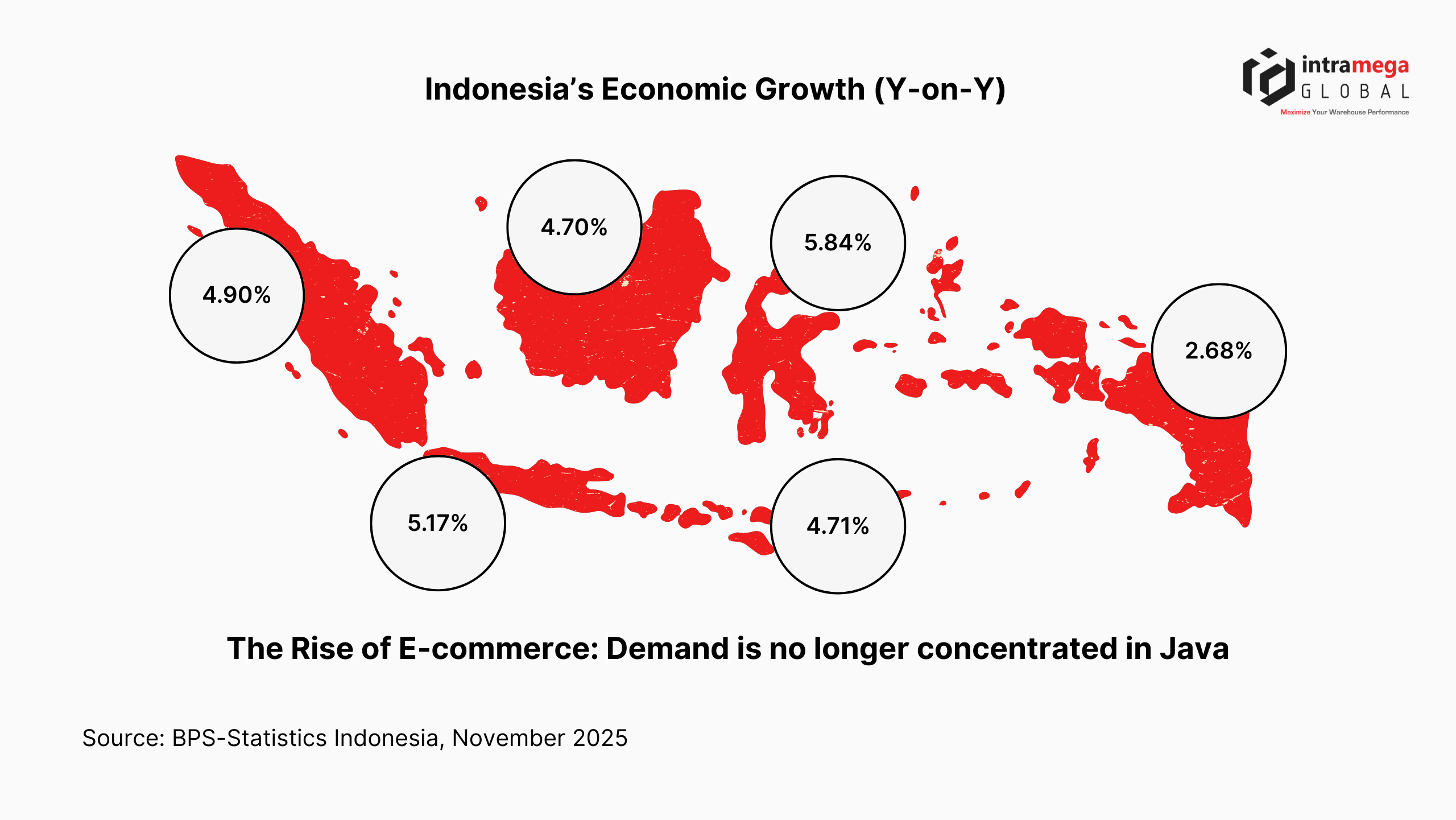

As e-commerce rises, consumer demand spreads beyond Java into Sumatera, Bali–Nusa Tenggara, and Kalimantan. This increases the need for modern, adaptive, and regionally distributed warehouses.

“Warehouses must be close to producers, but also close to the consumers,” said Intramega Global Director, Andi Wibisono. “If most demand comes from Kalimantan, then the warehouse should be in Kalimantan, not only in Java.”

This shift toward regional, decentralized warehousing reduces delivery times, lowers transportation costs, and supports national distribution more efficiently, especially in an archipelago where distance is a big, constant challenge.

Over the past few years, many e-commerce players have attempted to address this by building small to medium regional hubs. But the question is: Is that enough to meet Indonesia’s modern logistics demands?

Warehouses Must Evolve Beyond Storage

For decades, warehouses in Indonesia were built simply to store goods. But the rise of e-commerce has changed everything.

Consumers now expect speed, accuracy, transparency, and flexible delivery options.

“A warehouse should store goods, yes, but it should also serve as a distribution point, including for e-commerce,” Andi explained. “So there are many roles a warehouse must start taking on if we want to become more efficient.”

Today’s modern warehouse must play these 3 key functions:

- Optimized Storage: Efficient use of space, accurate inventory, organized SKU placement.

- Distribution & Fulfillment: Fast picking, packing, and outbound processes to support e-commerce and retail.

- Real-Time Operational Visibility: By using digital systems (WMS, scanning, RFID) to track movements, monitor performance, and make data-driven decisions.

The Major Barriers: Manual Operations, Skill Gap, and Investment Concerns

#1 Manual Operations

Despite rising demand, many warehouses still rely on handwritten logs, Excel sheets, and operator memory to track inventory and manage workflows.

This creates inconsistencies, delays, and costly errors.

“A warehouse can only be efficient if decisions are driven by data, not someone’s memory,” Andi said.

By adopting systems such as barcoding and scanning, Warehouse Management Systems (WMS), RFID, and automation, operations become faster, more accurate, and scalable.

Even small digital steps like standardizing receiving processes or implementing a basic WMS can create measurable improvements.

#2 Worker Skill Gap

There is a common assumption that Indonesian workers may struggle to operate advanced warehouse systems.

But from Andi’s perspective, “Many warehouses in Indonesia already use advanced automation, and they’ve proven they can be operated by Indonesian workers.”

The real need today is skill expansion by training more supervisors, operators, and managers who understand digital tools, workflows, and data-driven decision-making.

#3 Investment Concerns

Many businesses still view warehouse technology as an unnecessary cost. But it can changes with the mindset like this

“If technology can transform a warehouse from simple storage into e-commerce fulfillment, the value automatically grows. That is where ROI comes from,” Andi said.

So, instead of thinking about replacing labor, companies should consider how technology can:

- increases throughput

- reduces mis-shipments

- improves inventory accuracy

- expands warehouse capabilities

- enhances customer service

Why Modernization Matters for Indonesia’s Competitiveness

Indonesia’s logistics system will not become globally competitive through transportation upgrades alone. Warehousing also has a direct impact on:

- delivery speed

- inventory reliability

- logistics cost

- customer satisfaction

- national supply-chain resilience

“There is no choice but to pursue efficiency in logistics and warehousing. Technology adoption will increase, and integration across logistics providers must happen,” Andi concluded.

In an archipelagic country like Indonesia, warehouse may be the most immediate and impactful aspect to modernize.

Ready to modernize your warehouse?

Explore various digital systems that can transform your operations and add new values to your business.

Let’s talk! Contact us on Whatsapp: +62 811 9121 231